Broadcast

Adeas the specialists

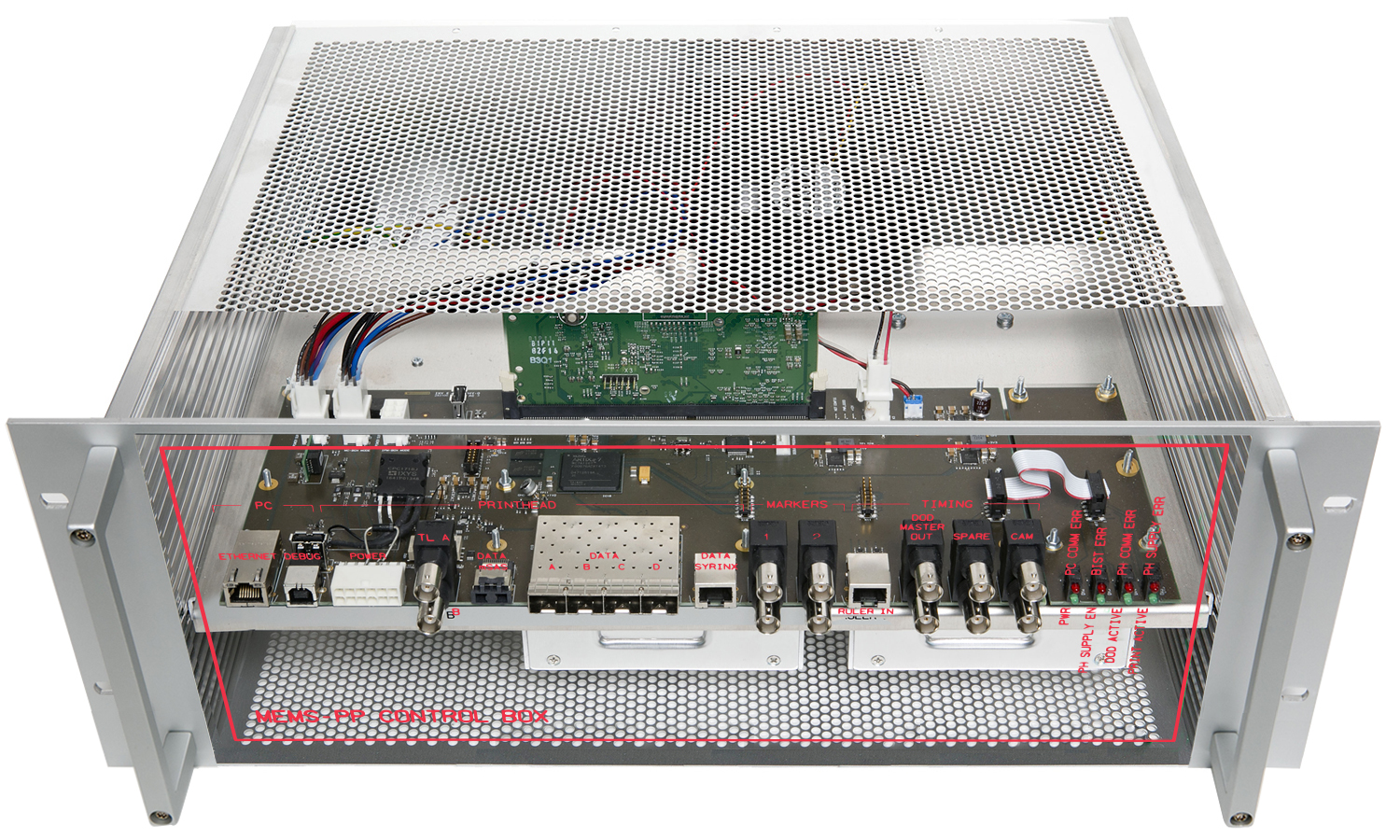

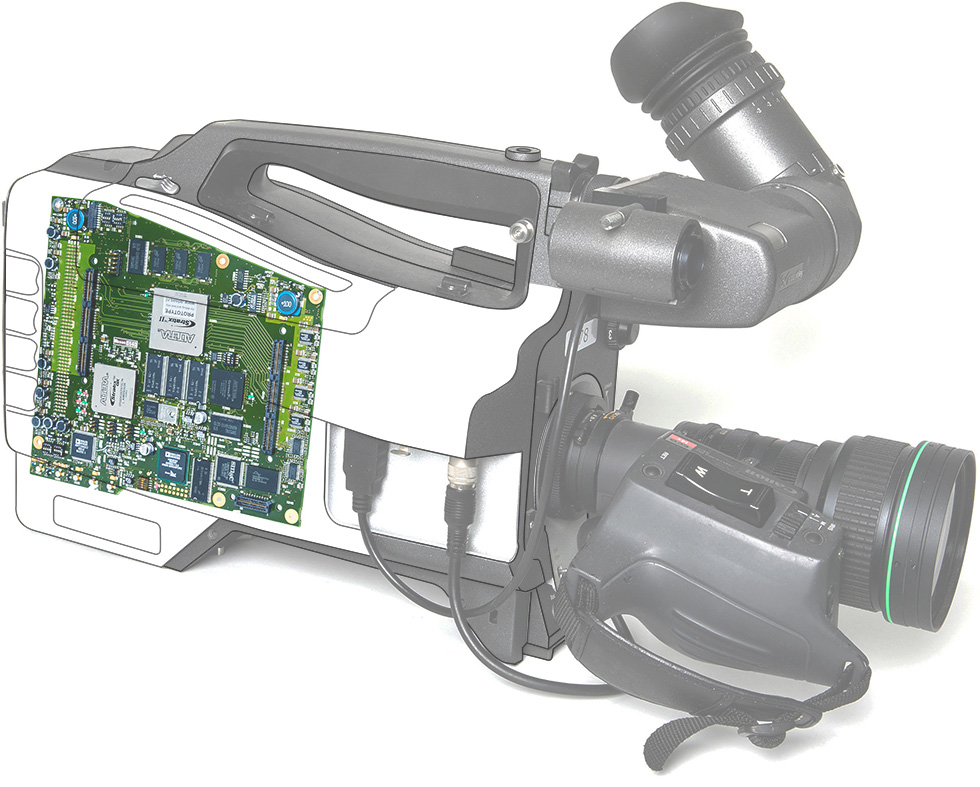

Since the founding of Adeas in 2005, we have been involved in developing FPGA content, boards, modules, specials and even whole products for our customers in the broadcast industry. From an electronics point of view, this high tech industry is dominated by the generation, processing, distribution and transmission of large quantities of data. Mostly uncompressed video with as little latency as possible. Thus the use of FPGA’s has always been a logical choice to process the high-speed data involved.

Adeas has gained huge experience in the whole broadcast chain starting with the sensors inside a camera up to and including displaying the video, audio and data on a monitor or television set.

Adeas has gained huge experience in the whole broadcast chain starting with the sensors inside a camera up to and including displaying the video, audio and data on a monitor or television set. We are executing projects in the area of image sensor processing, filtering, encryption, (forward) error correction, conversion, modulation, encoding and decoding up to driving the display panel. Virtually every standard used by this industry in the past two decades has been adopted and implemented in one or more of our projects. This puts Adeas in a very good position to be of service to companies that want to develop new functionality.

Adeas is also developing intellectual property (IP) cores to be integrated in FPGA’s or SoC’s which enable customers to make use of our experience and obtain proven solutions to integrate into their products. Although only a small portion of the RTL firmware we designed is available as an IP core you can find our portfolio here. Being a design services company we are certainly willing and able to provide design-in support or even a full design services project.

If this interests you or you want to find out if Adeas can help your company with the challenges you are facing, just contact us by phone or email.

| Tico / J2K / JPEG-(ls) |

| SMPTE ST2022-1,2,5,6,7 |

| HDMI 1.4, 2.0, 2.1 |

| Display Port 1.2, 1.4 |

| ASI, SDI |

| SMTPE-ST2110 |

| SMTPE-ST2059 |

| SD / HD / UHD, HDR, HFR |

| LVDS / Vx1 |

| 2D / 3D |

In recent years the broadcast industry is gradually moving from its own dedicated physical infrastructure and hardware towards more open and less proprietary market-oriented solutions. It seems the consensus is that the transfer of video, audio and data will gradually move from traditional standards over coax such as ASI and SDI to Ethernet based and go into the cloud thus making use of Internet Protocol. This is commonly known as Video over IP. Adeas already executed many Video over IP projects and we have developed and implemented solutions that comply with the standards the Broadcast industry has ratified.

Raw video or images originating from a sensor of some kind, almost always need to be corrected, filtered, compressed, scaled.

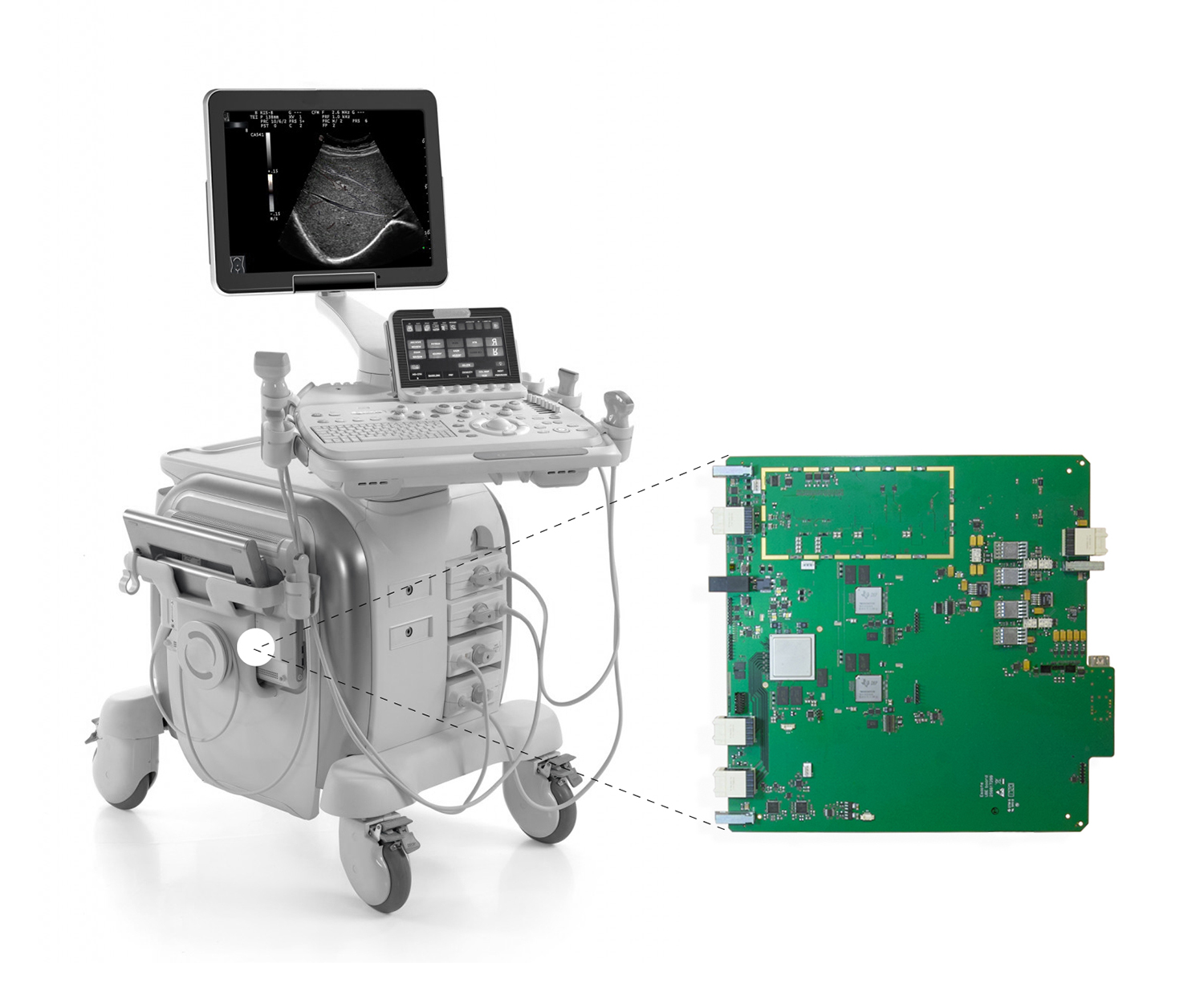

Video & Imaging

Raw video or images originating from a sensor of some kind almost always need to be corrected, filtered, compressed, scaled. Our experts discuss the wishes and possibilities with the client and look together for a way to achieve the desired goals. This may be using available commercially of the shelf (COTS) IP and/or implementing and testing new algorithms designed and owned by the customer on a hardware platform that allows for (real time) image processing. This platform can be especially developed to tailor fit the dimensions and processing power desired or be an already existing one. Almost always we use the FPGA’s or SoC’s from our partners Intel or Xilinx to implement the required functions.

Adeas has been involved in defining and executing projects involving video and or imaging issues throughout various markets. Varying from electronic solutions build for displaying on various (3D) displays to electronic signage or systems facilitating advanced visual collaboration. But also the projects we execute for copying & printing systems, radar, machine sorting and medical visualization often include video or imaging of some sort. At Adeas we understand the challenges that lay in handling, transporting and filtering the large quantities of high speed data involved.

Our clients can profit from the experience we have gained over the years and new talent entering our company gets to learn the trade from our skilled seniors. We can use cross industry tools and techniques that enable increased performance and/or improved efficiency.

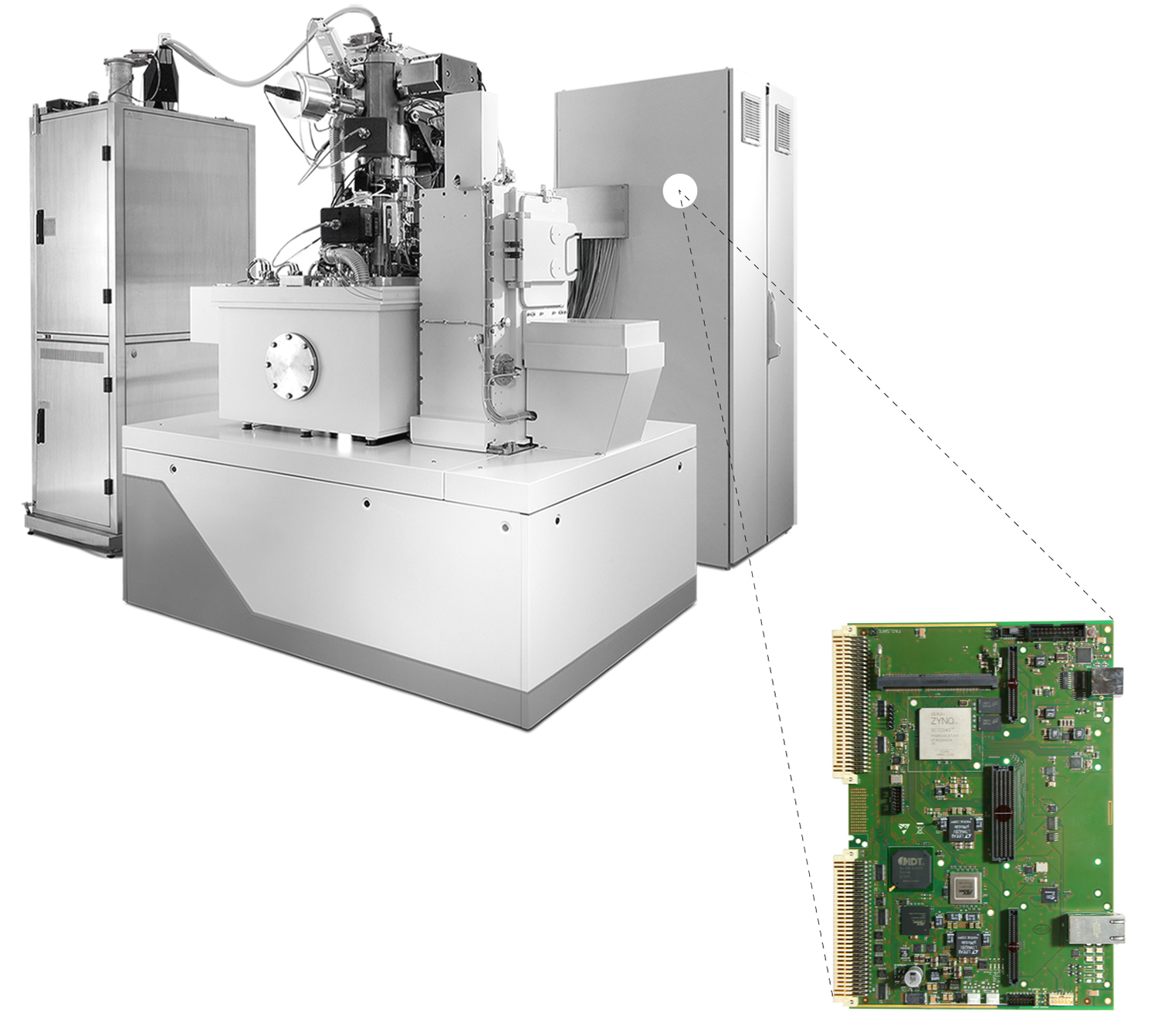

Adeas has a proven track record in designing advanced embedded systems and control that meets the requirements not only from a functional point of view, but also complies with the applicable rules and regulations.

High Tech Industrial

High tech machinery may require an advanced electronic system or control hardware that is not readily available and therefore has to be designed especially for the purpose. As this is costly the necessary investment must somehow lead to a return that makes the investment worthwhile. Adeas has a proven track record in designing advanced embedded systems and control that meets the requirements not only from a functional point of view but also complies with the applicable rules and regulations. As the electronics are a part of a machine that often involves other disciplines like optics, mechanics, mechatronics and pneumatics we work closely together with our customer making sure that no elements are forgotten.

Preferably, we get involved at the requirement specification phase up to and including integrating the realized solution which most of the time consist of hardware, firmware and (embedded) software. Optionally, Adeas can supply the electronic systems in series with warranty and life cycle management included.

The Adeas team involved, will investigate and discuss possible trade-offs with our client and together arrive at the best possible target to go for.

Test & Measurement

Adeas has been developing dedicated electronic test & measurement systems for our customers for many years. Mostly these are systems for measuring parameters and/or testing the functionality of electronic products or systems that our client is selling or using in its R&D department. Often, this functionality can’t be bought in a COTS (Commercial off-the-shelf) product because of the required procedure, specific (automated) measurements or high accuracy desired.

The development of such dedicated systems requires a close cooperation to obtain a thorough understanding of exactly what functionality is required, with what accuracy, speed, procedure and so on. The specification must be accurate and complete while often allowing for future extensions. Over specifying parameters or accuracy however can lead to significantly higher costs or even feasibility issues. The Adeas team involved will investigate and discuss possible trade-offs with our client and together arrive at the best possible target to go for.

Typically Adeas builds these systems in small quantities ranging from a single one to low or mid double figures making it more obvious to focus on saving on development time rather than on the bill of materials. Because at Adeas we consider a project a success when we succeeded in meeting the target resulting in a very satisfied customer.